American manufacturing is undergoing one of the most profound transformations in its modern history. The rapid integration of robotics, artificial intelligence, and advanced automation technologies is redefining what a factory can be and how it operates. Emerging companies, exemplified by innovators like Machina Labs, are demonstrating that high-level engineering can coexist with flexibility, creativity, and rapid prototyping at scales once thought impossible.

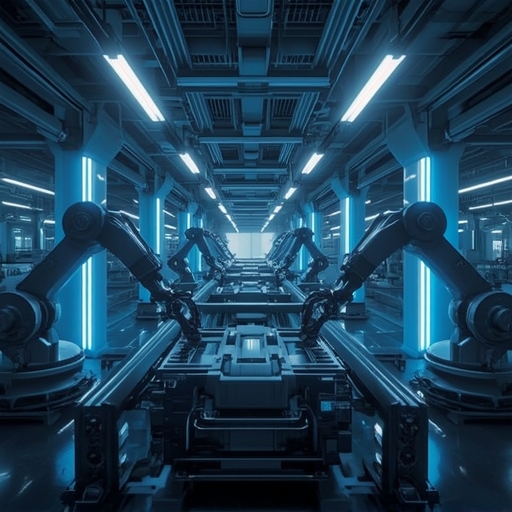

These pioneering firms are laying the groundwork for a new era in which robots are not simply tools of repetition but intelligent collaborators capable of adapting to changing production needs. By combining advanced sensors, machine learning algorithms, and agile manufacturing techniques, factories are becoming more responsive, sustainable, and efficient than ever before. Production, once constrained by rigid assembly lines and human limitations, is evolving into a dynamic ecosystem of adaptive machines capable of real-time decision-making.

What was once the domain of science fiction is now the new industrial reality: vast workshop floors populated by robotic arms that sculpt, weld, and shape materials with microscopic precision, illuminated by a symphony of data streams that continuously optimize performance. Within this environment, humans still play a vital role — not as repetitive laborers, but as creative engineers, designers, and problem-solvers guiding digital systems toward excellence.

Startups like Machina Labs represent the confluence of innovation and heritage. They bridge traditional craftsmanship with cutting-edge automation, ensuring that American production continues to thrive in a global economy driven by agility and intelligence rather than mere volume. This evolution challenges long-standing assumptions about what manufacturing entails — transforming it from a process rooted in uniformity into one driven by versatility and imagination.

The question for today’s industry leaders is no longer whether this transformation will occur, but how society will harness its momentum. Those who embrace the rise of autonomous manufacturing stand to redefine markets, empower local industries, and create resilient supply chains capable of withstanding global disruptions. The next industrial revolution has already begun, and its architects are the companies that see robotics not as replacement, but as reinvention.

In this moment of convergence between human ingenuity and machine potential, US manufacturing faces an opportunity to reclaim its pioneering spirit. Armed with intelligent systems and visionary design, it can shape a future where production is as much about innovation as it is about making — a future defined not only by efficiency, but by creativity, adaptability, and enduring progress.

Sourse: https://www.businessinsider.com/how-robotics-could-upend-the-us-manufacturing-industry-2026-2