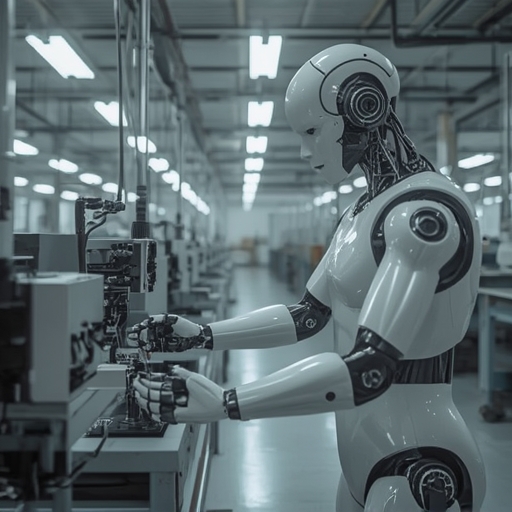

Tesla is preparing to take a bold and significant leap in its pursuit of advanced automation and artificial intelligence by relocating the training of its humanoid robot, Optimus, to the company’s renowned Austin Gigafactory. For the past year, Optimus has undergone an intensive and carefully monitored developmental phase at Tesla’s Fremont facilities, where engineers and AI specialists have progressively refined the robot’s dexterity, mobility, and problem-solving abilities. This forthcoming move to Texas marks more than just a change in venue; it represents a major milestone in translating laboratory advancements into applied, real-world skills.

Beginning in February, the Austin Gigafactory will become not only a production hub but also a center for pioneering experimentation in autonomous and semi-autonomous robotics. Tesla’s decision to expand the program to this location demonstrates the company’s confidence in its southern operations as a foundation for future-scale manufacturing. By integrating humanoid robotics directly into a large-scale production environment, Tesla is effectively creating a proving ground where cutting-edge research in machine learning, adaptive motion control, and AI-assisted manufacturing can converge.

The shift underscores Tesla’s broader vision to redefine the relationship between human workers, intelligent machines, and industrial efficiency. The introduction of Optimus into the Austin site will allow engineers to observe how robotic systems interact organically with existing manufacturing lines, identify potential workflow optimizations, and test safety protocols within real production conditions. In essence, this initiative symbolizes the tangible beginning of an era where human expertise and machine intelligence collaborate seamlessly in pursuit of productivity and precision.

This strategic evolution also highlights Tesla’s long-term ambition: to extend the influence of robotics far beyond automobile assembly. As Optimus refines its coordination and begins performing practical tasks, its success will provide insights that may shape future applications in logistics, infrastructure, and even domestic automation. The Austin deployment is both a continuation of technical progress and a statement of intent—affirming Tesla’s commitment to leading the global transformation of work through technological innovation.

While the project remains grounded in research and iterative improvement, the very presence of Optimus at the Austin Gigafactory signals how quickly science-fiction concepts are becoming daily reality. Tesla’s move from Fremont to Texas encapsulates the company’s defining philosophy: relentless innovation, adaptability, and an unshakable pursuit of efficiency through intelligence-driven design. The future of robotics and automation, once confined to prototypes and controlled testing spaces, is now materializing on the factory floor—right at the heart of the Lone Star State.

Sourse: https://www.businessinsider.com/tesla-optimus-robot-new-training-austin-gigafactory-2026-1